School Lockers for Everyone

Fall 2019

Description: We created a locking mechanism that allowed students with special needs at Broomfield High School to open their lockers by themselves. Our goal was to design a lock that the students could use in order to give them greater independence. One of the main requirements of the project was that the lock had to work with a plug-in switch which students are used to operating.

My role: I had Project Management responsibilities, and helped with building the prototype and the CAD for the bracket that held the special lock inside the locker.

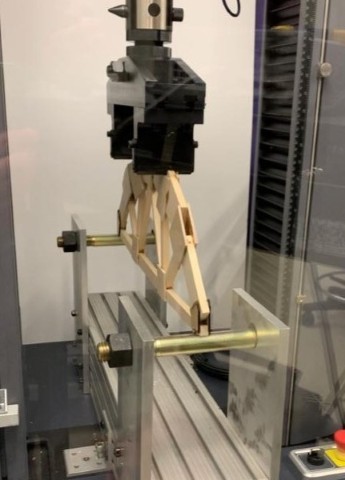

Truss Design

Fall 2019

Description: For a Statics class, we had to design and manufacture a truss. The goal was for it to be able to withstand 1200 pounds-force. After many calculations, along with testing for the most reliable wood and glue, we built our design. The truss weighed 0.682 lbs. and the final test was a four point test. It was successfully able to support 1381 pounds-force, failing due to shear stress.

My role: I worked on testing, prototyping, and manufacturing the trust.

Compressed-Air 3D-Printed Turbine

Fall 2019

Description: Our goal was to compare ideal and real values on the efficiency of a Thermodynamic Cycle. We built the system: compressed air ran through a 3D-Printed turbine which rotated the shaft of a generator. Temperature, pressure, and work output were obtained with thermo-couples, pressure gauges, and a multimeter, respectively. With such data, calculations were made, and results were produced.

My role: I calculated the ideal and real values of the efficiency of our system on EES (Engineering Equation Solver). Also, I helped with prototyping and testing.