Electronic Generala

Fall 2020

Description: This was the final project for “Circuit for Engineers”. It was an electronic version of the game Generala, also known as Yahtzee or dice Poker. The dice were represented by a circuit of 4060 microcontrollers and 6 LEDs each, showing the rolled value. A push-button is used to “roll” the dice. A counter system made of LEDs showed the time left in the game. A PCB divided the power from two 9V batteries into the counter and the dice portions of the project.

My role: I planned and built all circuitry. I was also the team leader, setting the vision and milestones for the project.

Thermo Guard: Cook Outside The Kitchen

Fall 2020

Desciption: Thermo Guard was a project for “Engineering Projects 3: Invention and Innovation”. This project involved creating a fictional business around a product and them building such product.

My role: I was the CFO, but apart from my financial duties, I was in charge of the programming and circuitry of the Thermo Guard. It was a device that sends data to an app, informing cooks about the state of the food, allowing users to “cook outside the kitchen”.

How Pan Material Affects Brownies

Fall 2020

Description: This was the final project for “Data Analysis for Engineers”. As a passionate baker (and cook), I have heard multiple well-know bakers recommending metal pans for baking brownies “evenly” across the pan. However, my personal experience said that glass or ceramic pans made for brownies with better “moisture”. I set the purpose of this project was to test that hypothesis: to identify how the pan material affects the overall humidity of the brownies and evaluate how humidity changes across the different locations of the slice. We used a humidity sensor to measure the brownie’s humidity for glass, ceramic, and metal plans and across the brownie slice (border, middle, and center). It was found that there was no statistical difference between ceramic and glass pans, and these were different from metal pans. Moreover, there was no statistical difference across the slice for none of the pan materials.

My role: As the team leader, I was responsible for road-mapping the project. Moreover, I baked all 9 batches (3 for each pan material) and helped with the measurements and data analysis.

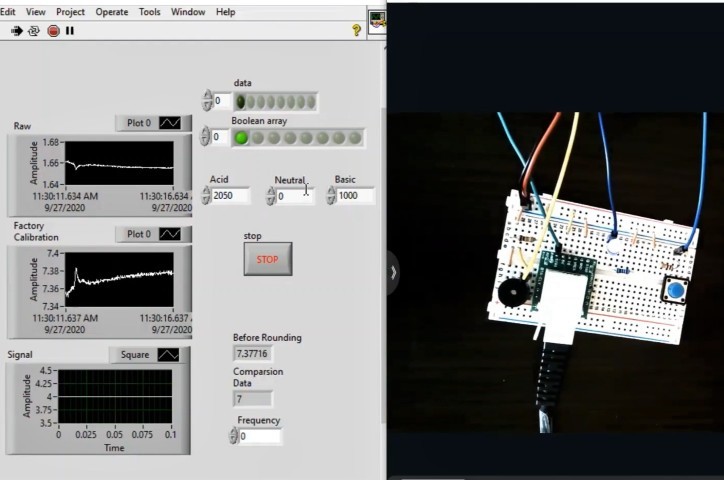

The Acidity Indicator, a pH Alerting Control System

Fall 2020

Description: For this “Data Analysis for Engineers” project, my client was a chef who wanted to find the acidity level of the perfect tomato sauce. Tomatoes are one of the most acidic fruits. As the base for tomato sauce, their acidity is always a concern. If the issue is not addressed, the result is an unenjoyable dish in which the acidity overwrites the other flavors. Therefore, a very methodic Italian chef (possibly myself) was interested in finding a way to detect this. To solve the issue, I created a control system for reading the pH levels of tomato sauce, with a speaker that warns the chef whether it is too acidic or too basic. I used LabVIEW to run the program and a data acquisition system, DAQ, to digitize the signals.The system turns on by pressing a button and an LED displays that it is functioning. The pH sensor then reads data, and depending on the pH level, the mini speaker (buzzer) alerts the chef.

My Role:I was the Engineering Consultant (and the client!).